Microwave Proofing System

Features

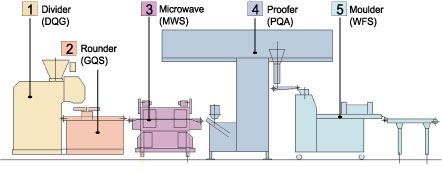

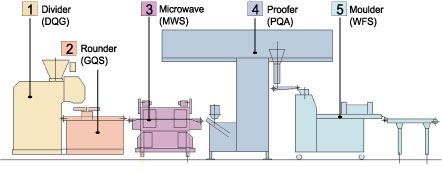

System layout

What is Microwave Proofing System ?

Divided and rounded dough pieces are irradiated by microwave to rise dough temperature about 5°C,

which leads to promotion of relaxation of dough structure, expansion of gas in the dough,

and acceleration/shortening of proofing time by helping fermentation of yeast.

Proofing time cuts down to half of conventional proofing time

- Graph 1 shows the comparison of conventional proofing and microwave irradiation treatment

for dough specific gravity after dividing and rounding dough.

Specific gravity after 15 minutes conventional proofing is equivalent to 7.5 minutes microwave irradiation treatment.

-

Graph 2 shows the comparison of pressure value required to the rollers when moulding the dough after dividing and rounding.

As same as specific gravity value, pressure value after 15 minutes conventional proofing is

equivalent to 7.5 minutes microwave irradiation treatment.

As result of these experiments,

microwave irradiation treatment can be cut down to half of conventional proofing time.

The quality such as taste, smell of bread make little difference from conventional Proofing.

Home line dough make-up equipment

1.Two rows small divider for connection of Gyrator

< Model DQG >

Compact Divider/Rounder to handle 30 to 230 grams of variety bread dough

- Cassette type of pocket to fit dough weight

- Advancement of cleaning by construction improvement of product zone

- Sanitation by separation of product zone and driving system/advancement of maintenance

2.Gyratory Rounder < Model GQS >

The first gyratory small rounder for variety bread

- Changeable rounding eccentric amount according to dough weight

- Variety rounding by easy cup replacement

- Easy daily maintenance with see-through cover

Model DQG specifications

| No. of pocket |

2 (Cassette type of pockets) |

Scaling

range |

30 - 230g |

| Stroke/min |

10 - 20st.

(every 2 strokes adjustable) |

| Capacity |

1200 - 2400 pcs/hr |

Hopper

capacity |

45 liters |

Required

electric |

main drive : 1.5kW |

Machine

dimensions |

W 810mm |

Machine

weigh |

Approx. 1000kg |

Model GQS specifications

Rounding

method |

Gyratory type |

No. of rounding

station |

1 station |

| No. of cup |

2cups x 5 = 10cups |

Required

electric |

up & down of cup

: 1.5kW |

gyration of cup

: 0.75kW |

conveyor drive

: 0.75kW |

spin roller

: 40W |

brush roller

: 0.1kW |

Machine

dimensions |

W 1333mm |

Machine

weight |

Approx. 1200kg |

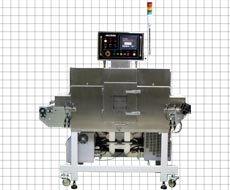

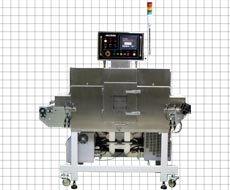

3.Two rows conveyor Microwave

< Model MWS >

Microwave rising temperature unit to promote relaxation of dough construction and to shorten proofing time

- Controllable output according to dough weight

- Continuous treatment in two rows

- Easy operation with programming selection

Model MWS specifications

Max. output of

oscillator |

2kW |

Treatment

capacity |

white bread (230g)

: 1500pcs/hr |

variety (30 - 110g)

: 2000pcs/hr |

Required electric

(Input Power

: 5kVA) |

oscillators

: 1kW x 2 |

conveyor drive

: 90W |

spin roller

: 40W |

shutter drives

: 40W x 2 |

Machine

dimensions |

W 1352mm |

| Machine weight |

Approx. 300kg |

4.Two rows belt driving proofer < Model PQA >

Belt drive type of proofer from new viewpoint

- Less noise and energy saving by using less metal.

- New design prevents food contamination.

- Easy removing tray

- Oil-free

Model PQA specifications

| No. of tray |

60 trays |

| Capacity |

2400 pcs/hr

(7.5min.as standard) |

| Proofing time |

7.5min.as standard |

| Dough weight |

30 - 230g |

| Required electric |

main drive : 0.2kW |

| flour duster : 90W |

| Machine dimensions |

W 1650mm |

| Machine weight |

Approx. 1500kg |

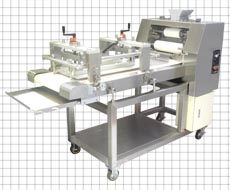

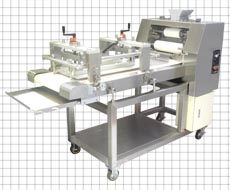

5.Single row moulder with infeed conveyor

< Model WFS >

New type of evolved moulder from the function of WF moulder

- Using two stages roller soft to the dough

- Reduction of dough damage by relief mechanism

- Digital display for adjustment

- Better cleaning and maintenance

Model WFS specifications

| Capacity |

230g : 3000pcs/hr |

| 30g : 4500pcs/hr |

| Dough weight |

30 - 230g |

| Dia. of rollers |

upper : 85mm

lower : 100mm |

| Roller clearance |

upper : 9 - 14mm

lower : 1 - 9mm |

| Roller speeds |

20 - 46m/min |

| Height of pressure board |

10 - 50mm |

| Range of width plate |

100 - 330mm |

| Required electric |

main drive

: 0.4kW |

| Machine dimensions |

W 3215mm |

| Machine weight |

Approx. 350kg |