This is a horizontal mixer for full-scale laboratory experiment with automatic dough temperature control system

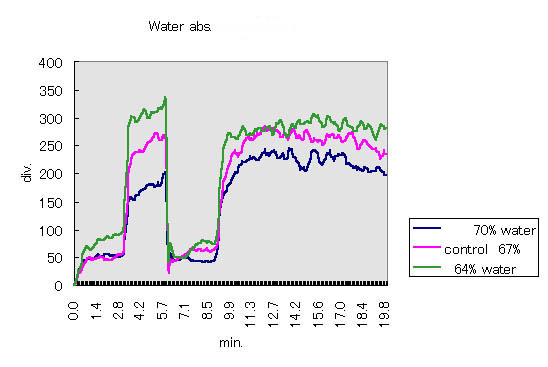

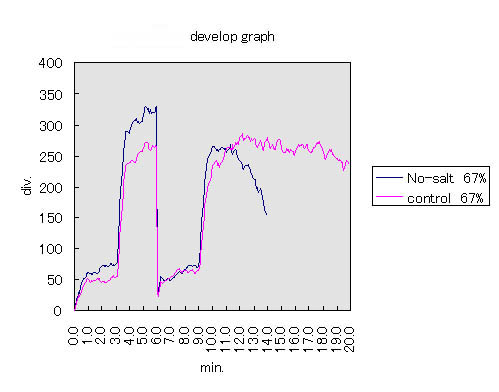

The data in mixing can be overlap with past mixing data. This can be compared at real time.

Additional function of sensor groups can be optional to analysis advanced dough

| HM-50 | |

|---|---|

| Model | HM-50 |

| Mixing Dough Weight | 23kg (Dough weight) |

| Main Drive | 5.5kw, (Inverter) |

| Agitator | Type YY-2 |

| Agitator Rotation Speed | 50-150rpm (3 Speed) |

| Power supply | AC200V 3Phases 6kw |

| Chiller Unit | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature control range | 0 - 50℃ degrees centigrade | ||||||||||||||||

| Electrical to be required | Chiller : 0.6 kw , Heater : 2.25 kw | ||||||||||||||||

| Power supply | AC200V 3Phases 3.5kw | ||||||||||||||||

| Display and Sensors | |

|---|---|

| Display |

|

| Optional sensors |

|

Note) Specifications and dimensions may be subject to change without prior notice.

Note) Supply voltage is in accordance with the one in the country machine is used.

Transformer might be needed according to the specifications

| Display/Record | |

|---|---|

| unit weight |

|

| unit size |

|

| Standard to be displayed |

・Develop Graph ・Mixer motor power graph (★Other sensor output as optional can be possible) |

| PC to be used |

|

| OS to be used |

|

※This product can be shipped with the mixer already installed.

Please contact us if you would like to have it installed in other ways.

As example of mixing for white bread,

optimum mixing time in most of cases is time just after develop peak is passed in one to two minutes.

(This will be changed depending on recipe and breads, etc).

Here is shown in over mixing to explain the develop peak of dough.

Please feel free to contact us.

Click here to contact us