| For Soft Dough: | : | YY2 Agitator or YY2A Agitator |

|---|---|---|

| For Hard Dough | : | YY1 with HP up motor |

| ※ | Possible to use YY2 with HP up motor for Hard dough |

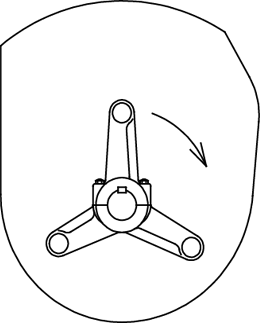

YY1

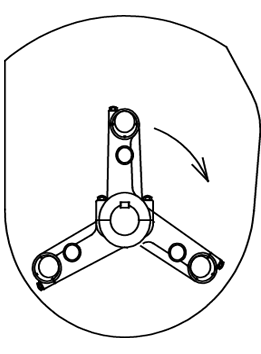

YY2

|

|

|

|

YY1 |

YY2 |

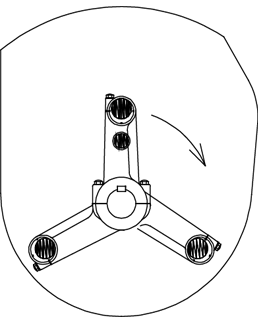

YY2A |

|

|

|

|

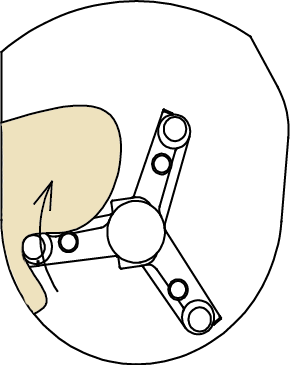

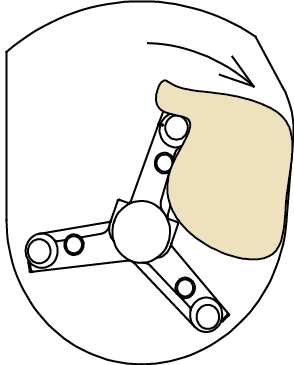

・CATCH DOUGH |

・PUNCHING THROW DOUGH AGAINST BACK SIDE OF BOWL |

・KNEADING STRETCH DOUGH AT BOTTOM SIDE OF BOWL |

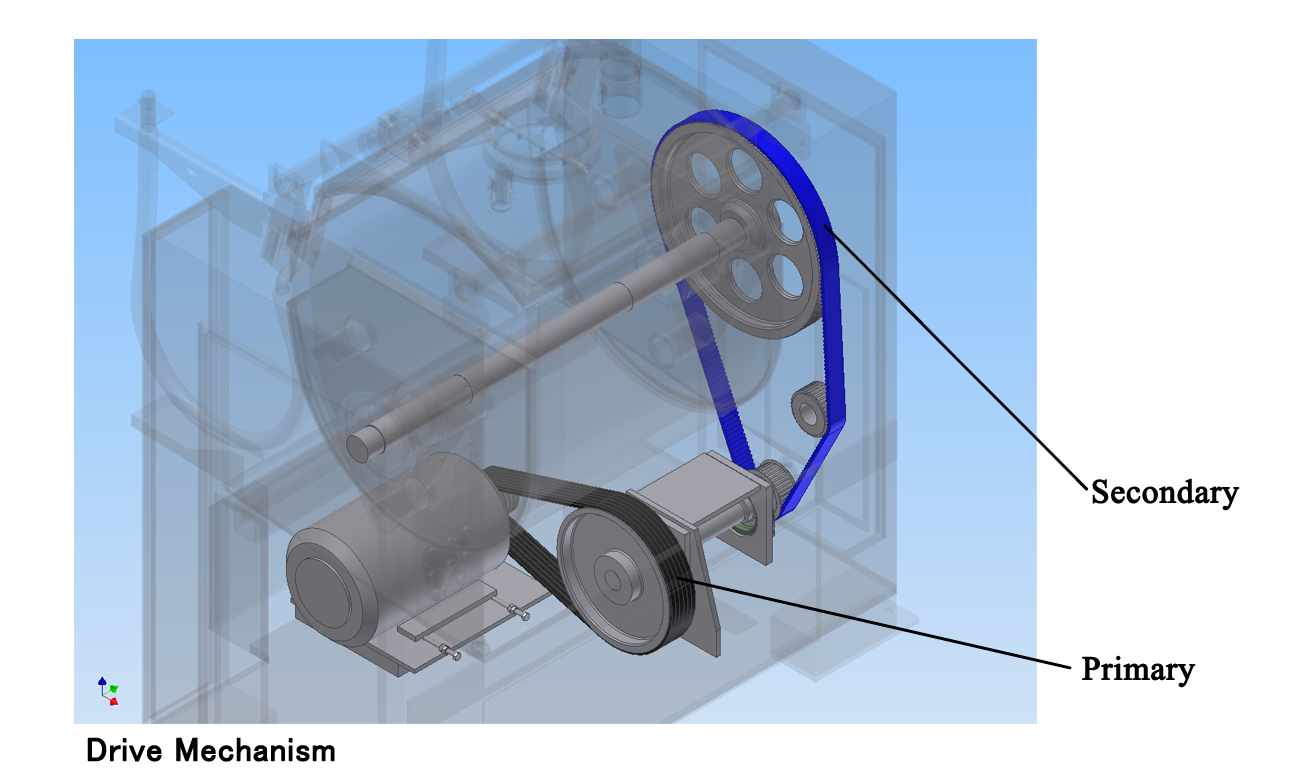

Chain

Timing Belt

Drain inside of frame

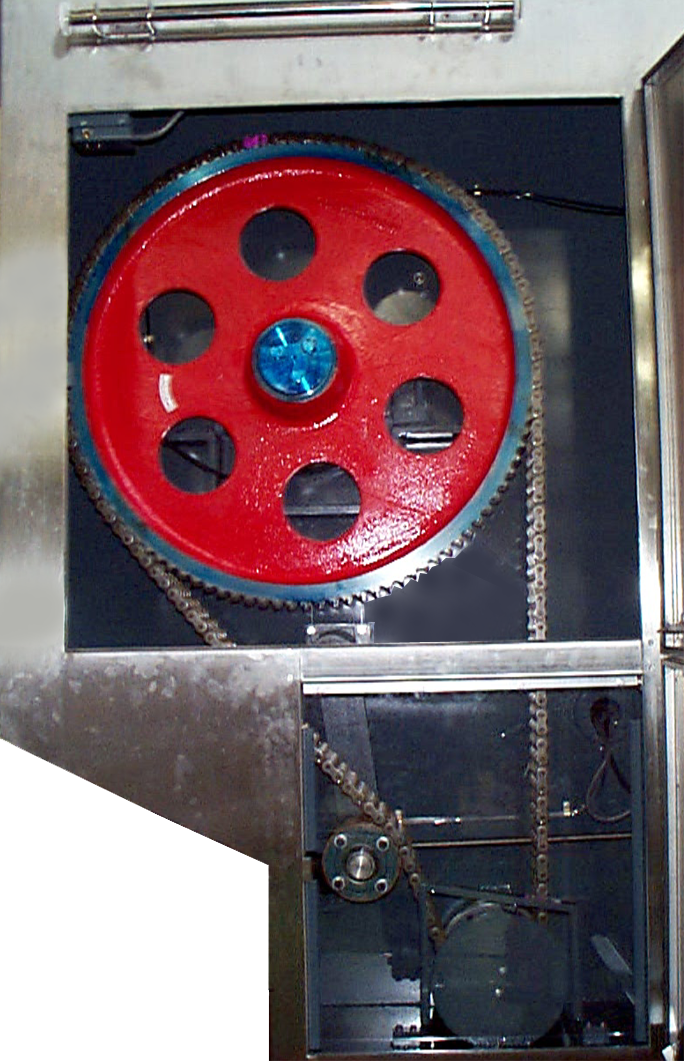

HM2000-120T

HM1600

Please feel free to contact us.

Click here to contact us