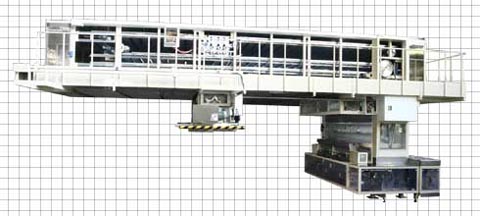

'BREAD' Line

Oshikiri provides you with a Fully automatic and/or Semi

automatic production system for White Bread in compliance with your

requirements such as production rate, number of dough pieces per

baking tin, shape of the dough panning, etc.

State of the Art Design for utmost quality and loss-less production.

Divider

DKX

| No. of pockets |

Scaling (g) |

Capacity (pcs/h) |

| 5 |

240 - 600 |

3,000 - 7,500 |

| 6 |

200 - 520 |

3,600 - 9,000 |

Dough Divider Model DKX

-

Precision and Flexibility

Pressure feed to dough changeable, divides dough with optimum

pressure. Sucking stroke of main ram and knife changeable.

Sucking stroke of main ram and knife changeable. Flexible

setting of dividing mode and timing of each component with a

basic program in compliance with dough weight and machine speed.

Optional Auto-checker system enables highly precision dividing

weight compensation even when batch shifting (only for model DKX

& DMX).

-

Long Life

Replaceable front & bottom plate of dough chamber (i. e.

sliding part) just by screwing.

Division head does not contact with sliding parts.

Replaceable dough chamber just by screwing.

Lubricating amount adjustable point by point for

auto-lubricator.

-

Easy Cleaning

Components moves to cleaning position by one touch on touch

screen.

Equipped with cleaning aid device for main ram and knife.

Even flip side easily cleaned.

-

Maintenance saving

Easily accessible configuration.

One-touch replaceable conveyor belt.

Lubricating points decreased by 50% in comparison with our

conventional model.

Touch screen displays a message for lubrication when it is time.

Rounder

Vertical Rounder Model RV500

-

In consideration of dough weight, correlation of the rounding

track and drum is designed to achieve optimum rounding effect.

-

The rounding track divided by 45 degree; easy to change rounding

length, easy to replace.

-

Maximum length of the rounding track 4400mm which is longer than

existing Model "RK" rounder by 2000mm. (Standard 1

3/4 wind)

-

Special coating applied to the rounding track and the drum.

Highly wearable.

-

Infeed at bottom and discharge at top facilitate easy connection

with divider and proofer.

-

Longer discharge chute helps appropriate cover of the dough

pieces with dusting flour.

-

Hygienic due to the sufficient space between the drum and the

support base.

-

Equipped with a discharge chute and a catch box for doubled

dough pieces.

RV500

| 250 - 500g |

7,200pcs/h |

Intermediate Proofer

Intermediate Proofer Model PG/PM/PK

-

Resin made cups can be exchanged by one-touch for easier

sanitation.

-

Residue Catch Pan is located under drive chain to prevent

foreign objects from being mixed.

-

Single operation system continues working even when the prior

equipment stops, no dough is wasted.

Intermediate Proofer

| PG |

8 or 12rows |

30 - 400g |

| PM |

6 or 12rows |

30 - 500g |

| PK |

6 or 12rows |

100 - 700g |

Moulder

Cross Moulder Model MKC

-

Optimum moulding performance by independent drive and valiable

speed for Sheeting Roller and Moulding Belt.

-

Mainly suitable for large size dough pieces for white bread.

-

Step-by-step sheeting with large diameter rollers minimizes

damages to the dough.

-

Lightly moulded since curling line cuts sheeting line at right

angles.

-

Incorporating the Pressure Board provides more consistent

moulding in the shape and quality.

-

Digital indicators for the roller and belt speed and the height

of the Pressure Board makes adjustment easy.

| 220 - 520g |

4,000pcs/h (520g) |

| 4,500pcs/h (360g) |

Bread Panner

Automatic Bread Panner Model APS

Alternative shaping from "M" type, "N" type and

"U" type.

Deformed dough pieces are automatically removed before panning.

Image Sensor and Servomechanism facilitate faster and more accurate

panning.

Manual shaping is possible when using Bypass Conveyor.

Bread Panner

| up to 520g |

4,320pcs/h |

| M shape |

3 or 2 pcs available |

| N shape |

4 pcs available |

| U shape |

5 pcs available |